Pipe

High-Performance Steel Pipes for Reliable Oil Well Completion

Casing & Tubing Pipe

Our Casing & Tubing Pipes include a full range of non-upset and external-upset tubing

in steel grades H40, J55, K55, and N80.

Manufactured in accordance with API Spec 5CT, they offer stable, reliable quality

and fully meet the operational needs of oil field extraction.

Application

Oil extraction, Transportation of petroleum, natural gas, water, mineral slurry, coal gas and other confined long–distance transportation pipeline, Large project constructions

Standard

API Spec 5CT

Steel Grade

H40(Basic), J55, K55, N80(Strong)

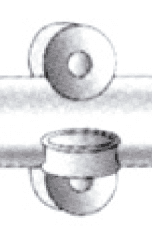

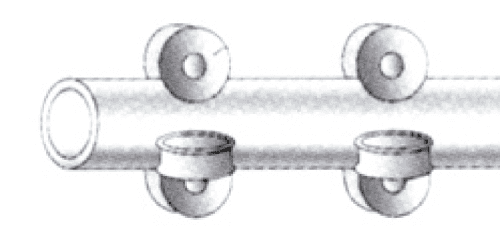

End Type

Non-upset tubing, External-upset tubing

Welding Method

HFW (High-Frequency Welding)

Pipe Length

8 -12.5m

| Production Range

| Advanced Equipments & Manufacturing Capacity

Advanced FFX rolling mill (Japan)

Reliable on-line and off-line UT inspection equipments (Canada)

High-speed medium-frequency heat treatment machine (America)

Skelp Accumulator

High-speed cut-off flying saw

Hydraulic pressure testing unit

Steady solid high-frequency welding machine (America)

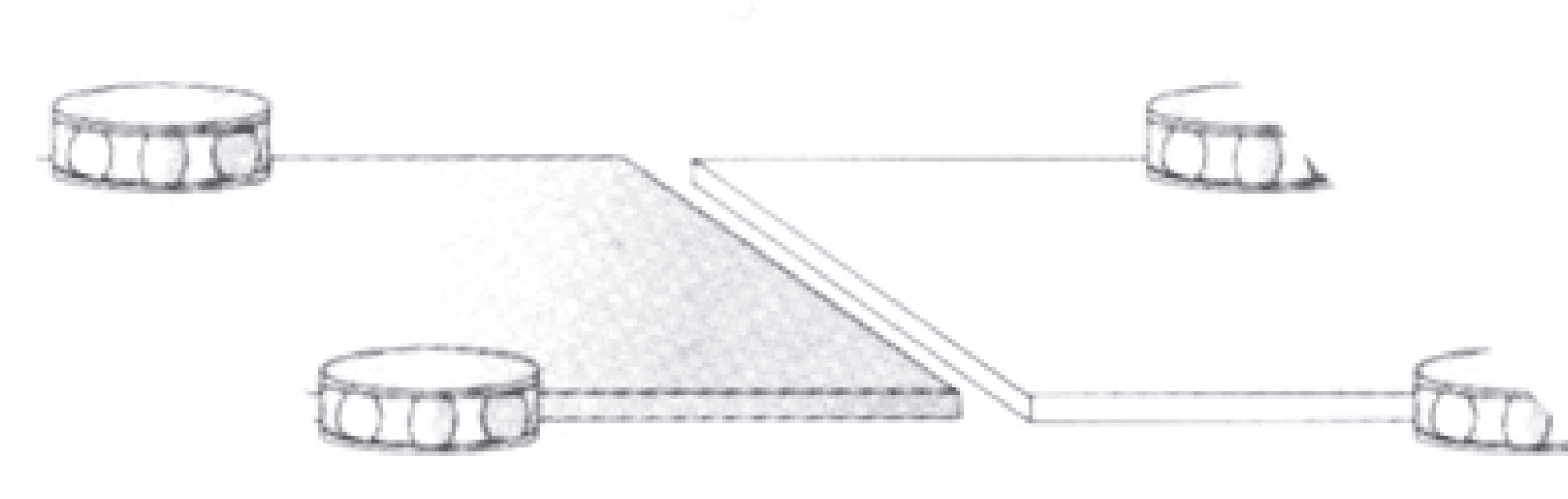

| Manufacturing Process

| Inspection Instrument and Equipment

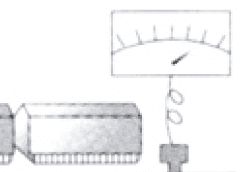

Spectro direct-read spectrometer

(26 kinds of chemical element can be inspected)

Digital displayed hydraulic pressure universal machine

Impact testing machine

Drop weight tear tester

Metallographic microscope

Hardness tester & Flattening tester

Carbon & Sulfur analysis instrument

Bending Testing Machine

100% basse metal automatic ultrasonic testing

100% X-ray inspection

computer recording system

100% ultrasonic detect after hydro-test

100% pipe end manual ultrasonic detect

100% steel pipe visual inspection

100% internal weld industrial television

Magnetic particle test